Cheaper deep-freezing and liofilisation

Food industry • Fish-processing industry • etc.

Cheaper storage of frozen products

Warehousing • Food industry • Fish-processing industry • Catering services • etc.

The existing technologies for regasifying liquefied natural gas (LNG) expend huge amounts of energy, either burning part of the gas or use seawater as heating source, thus causing air pollution or harm to marine life. Costly and over dimensioned equipment must be installed to guarantee trouble-free operation of regasification plants. Nevertheless, icing, leakages and swath formation are an issue at many regasification sites using ambient air vaporizers.

LNGcold advancedREGAS reduces operational risks and environmental effects: Extracting the cold energy from LNG during the regasification process not only minimises operational problems, safety risks and costs, but also increases the regasification capacity of the plant itself. The LNGcold advancedREGAS technology can be easily integrated in existing or new regasification plants.

See more information about operational risks and environmental improvements

During the common regasification process almost all the cryogenic energy of LNG is lost. This translates into several GW of valuable cold energy lost worldwide constantly, which could be applied for industrial value creation and other cooling applications.

Thanks to LNGcold advancedREGAS, highly valuable deep cold at e.g. -60°C can be provided with zero emissions of CO2 or other pollution for a variety of applications.

Together with energy-efficient production or refrigeration equipment the recovered cold energy from LNG allows the creation of complete new value chains at very competitive operational costs.

Additional industrial processes, now competitive in production costs even in smaller sizes and capacities, allow profitable investments where a next step in value added to products was not possible before. Thus, additional employment, gross domestic product as well as tax revenues can grow.

The demand for cold for industry, food handling and climatisation is globally growing by 1-2% p. a. and the replacement of costly and environmentally harmful compression technology (state-of-the-art) is pressing. It is estimated that electrical refrigeration and air-conditioning consumes almost 25% of the electrical energy in Europe, a tremendous saving potential.

Thanks to the LNGcold advancedREGAS solution, highly valuable deep cold can be provided with zero emissions of CO2 or other pollution. Compared to the traditional compression technology, this can be translated into a 100% decrease of CO2 emissions and pollution.

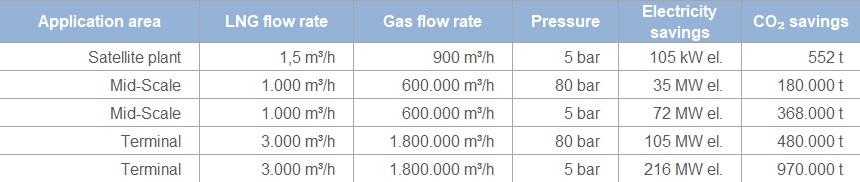

The following chart shows the savings in electrical energy and CO2 that could be generated, if the cold energy contained in the LNG would be recovered with the LNGcold advancedREGAS technology to substitute conventional compression cooling technology:

During regasification of approx. 3,000 m³/ h LNG into 1.800.000 m³/h natural gas, 200 MW refrigerating capacity is lost to the environment. At a LNG terminal (port), more than 100 MW refrigerating capacity at down to -50°C can be recovered at a pressure of 80 bar, substituting 100 MW el. and saving more than 480,000 t/a CO2.

This data of a real European LNG regasification plant at a LNG terminal (port) shows the tremendous effect of the LNGcold advancedREGAS solution on environment protection. The worldwide introduction of a LNG cold recovery process would therefore contribute substantially to achieving the climate targets.

Cheaper deep-freezing and liofilisation

Food industry • Fish-processing industry • etc.

Cheaper storage of frozen products

Warehousing • Food industry • Fish-processing industry • Catering services • etc.

Cheaper cold for manufacturing processes

Cryogenic recycling • Chemical industry • Air separation • Plastics processing • Wood processing • Compounds and composites • Pharmaceutical industry • etc.

Cheaper production of cold subproducts

Ice cubes • Dry ice • Dry ice granule for cryoblasting

Weather-independent operation of sports and leisure facilities

Indoor ski trails • Ice skating rinks • Theme worlds or arctic adventure parks

Your application

Get information about how your business can benefit from an economic supply of valuable cold